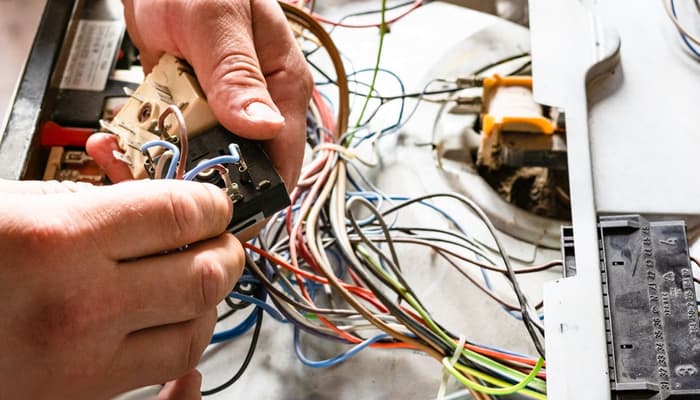

In today’s generation-driven international, we regularly neglect the complex craftsmanship in the devices and structures we use every day. One such critical yet frequently omitted position is that of a cable assembler. But what does a cable assembler assembler do? Cable assemblers are professional specialists liable for assembling, checking out, and ensuring the best cables are used in various digital devices, machinery, and verbal exchange systems.

From complicated vehicle wiring harnesses to sensitive fiber optic cables in telecommunications, those professionals play a critical role in powering and connecting the cutting-edge world. This article will dive deeper into the responsibilities, talents, and significance of cable assemblers, shedding light on this crucial but underappreciated career.

What skills do you need as a cable assembler?

As a cable assembler, you need these skills

- Attention to Detail

- Manual Dexterity.

- Soldering Proficiency

- Basic Electrical Knowledge

- Technical Reading Ability

- Troubleshooting Skills

- Hand Tool Proficiency

- Quality Control Awareness

- Time Management

- Communication Skills

- Safety Consciousness

- Patience and Focus

What does a cable assembler do

Step 1. Understanding Job Requirements

Before starting work, a cable assembler thoroughly opinions the task specs. These instructions typically consist of designated diagrams, measurements, and fabric lists essential to gathering the cables. Understanding these blueprints ensures the very last product meets purchaser specifications.

Step 2. Gathering Tools and Materials

Once the assembler understands the task, the next step is to acquire all required equipment and substances. This consists of the whole thing from wires and connectors to insulation materials, soldering irons, and checking out devices.

- Collect wires, connectors, and cables

- Ensure the availability of soldering tools

- Set aside safety gear (e.g., gloves, glasses)

Step 3: Preparing the Work Area

A smooth, organized workspace is important for cable meetings. Cable assemblers prepare their workplace by way of arranging tools and materials in an on-hand manner.

They also ensure the location is unfastened from clutter to prevent accidents and maintain productivity. Cleanliness reduces the chance of contaminants interfering with sensitive digital additives.

Step 4: Cutting Cables to Length

Once the substances are equipped, the assembler starts offevolved by way of reducing the cables to the specified lengths. Using precise measurements is prime to ensuring the cable suits effectively in its intended application.

Cutting the cable too short can render it useless, at the same time extra periods can create useless bulk and inefficiency.

Step 5: Stripping the Cable Ends

After reducing the cables, the next step is to strip the insulation from the cable ends, exposing the conductive wire internally. This is generally accomplished using twine strippers.

The assembler ought to be careful no longer to damage the underlying wire while doing away with the outer insulation. This step prepares the cables for the attachment of connectors.

Step 6: Crimping or Soldering Connectors

Depending on the kind of cable and its software, the assembler will either crimp or solder connectors to the uncovered wire ends. Crimping involves the usage of a crimping device to connect connectors securely, even as soldering requires the assembler to soften solder to create an electrical connection. Both techniques are important for ensuring proper connectivity.

Step 7: Applying Insulation and Heat Shrink Tubing

- Slide warmness reduces tubing over the relationship factors

- Use a warmth gun to reduce the tubing tightly over the relationship

- Apply additional insulation if needed to bring protection and durability

This step allows to enhancement of the connection and provides a layer of protection against external harm, moisture, or electric interference.

Step 8: Assembling Multi-Conductor Cables

Multi-conductor cables require assembling numerous wires into a single cable. This includes bundling the individual wires together, routing them through a protective jacket, and connecting every wire to the suitable connector.

This step requires interest in the element and an amazing know-how of the way each wire features inside the cable.

Step 9: Testing Cable Assemblies for Continuity and Functionality

Before a cable assembly is considered entire, it ought to be examined for continuity and capability. Using a multimeter or cable tester, the assembler ensures there are not any breaks within the circuit and that the connectors are well attached.

Functional checking out may also be performed to make certain the cable plays its meant cause in a system.

Step 10: Troubleshooting and Reworking Assemblies

If checking out reveals any troubles, the cable assembler must troubleshoot the hassle. This ought to involve checking for loose connections, repairing damaged wires, or re-crimping connectors.

Troubleshooting ensures that the final product meets all excellent and performance requirements earlier than it’s far brought to be used.

Step 11: Documenting the Assembly Process

Accurate documentation is a vital part of cable assembly. The assembler maintains statistics of each step within the system, noting any challenges or modifications

. This documentation guarantees traceability and allows destiny troubleshooting or production runs. It additionally provides a reference for pleasant management audits.

Step 12: Maintaining Quality Control Standards

Cable assemblers have to adhere to strict first-class management standards, frequently dictated using the industry they work in. This includes ensuring that every cable meets protection guidelines and characteristics efficiently.

Regular inspections and high-quality assessments are conducted at some stage in the assembly method to hold those requirements.

Conclusion

Cable assembly can also seem like a straightforward project, however, it requires a mixture of technical ability, interest in detail, and a strong expertise in electronics. Cable assemblers play a vital function in industries that rely upon precise and dependable cable structures.

By following structured steps, from studying blueprints to carrying out final assessments, cable assemblers ensure that their merchandise meets high overall performance standards.